12.3. Connection elements#

Nails#

For the connection of thinner parts to a thicker part, nails are very suitable because the thin nails have a relatively high bearing strength per surface area. Nails are inserted perpendicular to the timber and must be inserted from both sides for double planed joints. Nails are not suitable to transmit forces along their longitudinal axis for long periods of time (the nails are pulled out). A nailed connection behaves in a way that for trusses the nailed joints can be assumed to be hinged. The nails can have a diameter of 1 to 8 mm and vary in length, from 40 to 200 mm.

Bolts and dowels#

Fig. 12.38 Bolted connection#

The bolts used are the same as in steel construction with material quality 4.6 or 8.8. The holes for the bolts are predrilled and assembled with a washer to prevent damage to the timber. The predrilled holes are usually slightly larger than the bolts to ease assembly. This causes the bolted joints to deform relatively much under service loading. Bolted joints are therefore only applied in connection where this behaviour is acceptable.

If large deformations are not acceptable bolts can be combined with split rings or toothed plates to increase the joint stiffness.

The stiffest joints can be made using dowels. Dowels are pressed mechanically in precisely fitting predrilled holes. To prevent the joined parts from separating a few additional bolts are necessary. The dowels are plain round steel rods with a diameter of 8 to 24 mm using different steel grades. The forces between the elements are transmitted through the dowels en due to the method of assembly little deformation will occur under service loads. This makes the doweled connection suitable for permanent structures. Even moment resisting joints can be designed capable of carrying relatively large forces.

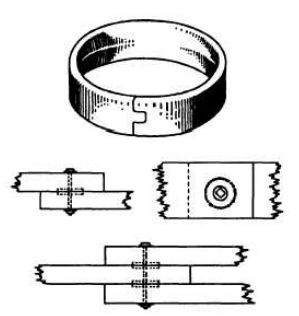

Ring and shear plate connectors#

Fig. 12.39 Example of a split ring connection#

Split rings are placed in a circular moulded groove which is milled in in advance. Forces are transmitted by compressive stresses between the ring and timber. Generally a bolt is added through the ring to prevent separating of the elements.

Shear plate connectors consist of thin metal plates placed in moulded grooves. The grooves are shaped such that the plate is mostly integrated in the timber element and an efficient force transmission is possible. Shear plate connectors are often used in combination with cold formed steel fasteners.

Ring and shear plate connectors are applied with diameters ranging from 60 to 260 mm.

Toothed plates#

Fig. 12.40 Example of a toothed plate#

Toothed plates are thin steel plates which are provided with triangular teeth at their circumference. The forces are transmitted trough the teeth to the plates itself which in turn loads the connecting bolt. Toothed plates are pressed into the timber, limiting their use to the softer species like European pine. Toothed plates can be ordered one sided or two sided. The stiffness of the joint is determined by the toothed plate, while the strength of the joint is determined by both the plate and the bolt. Toothed plate joints can be assumed as hinges. One sided toothed plates can also be used as connection between timber and steel or timber and wood. The plates can even be used in a demountable structure.

Toothed plates with a diameter of 50 to 62 mm are used in combination with bolts ranging from M10 to M16. Toothed plates with a diameter of 75 to 117 mm are used with bolts M10 to M24. The minimal thickness of the connecting elements for the toothed plates from 50 to 117 mm ranges from 20 to 58 mm. The connections must be placed conform to the normative edge distances. For loaded edges this is 50 to 120 mm and for unloaded edges this is 40 to 90 mm.

Coach screws#

Fig. 12.41 Coach screw#

Coach screws are very suitable for application on site. The screws are usually of grade 4.6 with a diameter of 10 to 16 mm. With coach screws only very low tensile forces can be taken. Coach screws are therefore mostly suitable for shear connections. The screws are usually combined with metal plates (see: cold formed steel fasteners). Holes are predrilled to prevent splitting of the wood.

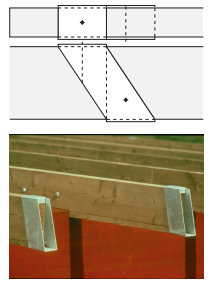

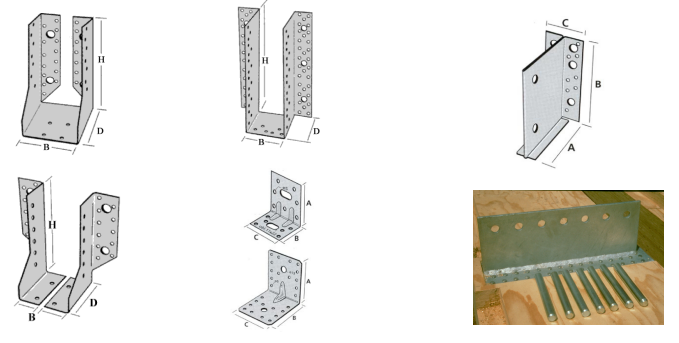

Cold formed steel fasteners: joist hangers, integral fasteners and angle brackets#

Fig. 12.42 Connection to elongate a beam (shear force splice)#

Cold formed steel fasteners are made of steel plates by cold deformation or welding. The fasteners are used to connect or support timber elements. The steel must be of sufficient quality and galvanized by a continuous process. Cold formed fasteners applied at a relative humidity over 90% must be made of stainless steel or must be fully protected against moisture. The coating must be resistant against mechanical damage caused by normal use. The fasteners are categorised according to force flow and shape. The forces can be transmitted by support planes or with additional connection elements (nails, screws, dowels, etc.).

Connections made with cold formed steel fasteners show little deflection under service loading and are therefore suitable for permanent structures. The maximum load depends on the type of fastener and the number of connection elements (nails, screwes, dowels etc.). The behaviour of the fasteners is very close to a hinge and can be assumed to be fully hinged. If the fasteners are not loaded symmetrically the maximum load is reduced an large deformations can occur. This is therefore only allowed in exceptional cases.

Fig. 12.43 Possible shapes#

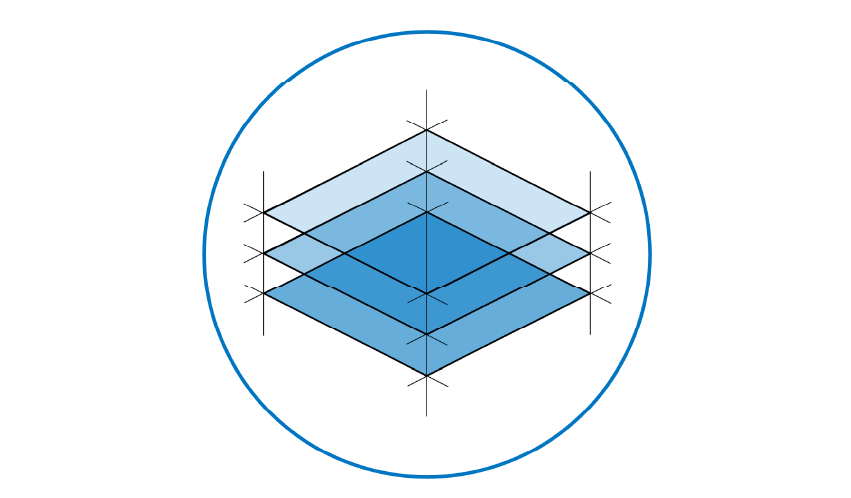

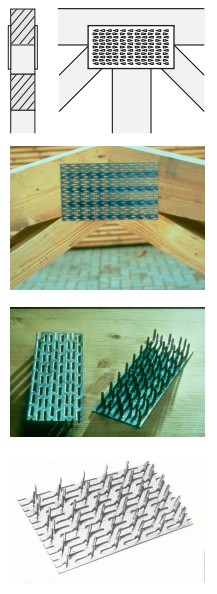

Punched metal plates#

Fig. 12.44 Examples of punched metal plates#

Punched metal plates are thin galvanized plates with a thickness of 1 to 2 mm. On one side the plates are provided with protruding metal teeth. The connections made with punched metal plates are only suitable for statically loaded structures. The plates have a standard width while the length can be varied. The connecting elements need to have the same thickness. The plates are placed on both sides of the connection and pressed into the timber. Therefore this connection is only suitable for softwood. Forces are transmitted only by the teeth and the plate giving a behaviour close to a full hinge. The maximum capacity of the joints mainly depends on the tensile strength of the timber, the strength of the metal plate and teeth. The orientation of the plate in relation to the axes of the connection elements and the load orientation are very important. The capacity of punched metal plates cannot be combined with other connection types due to its deformation behaviour.

This type of connection is mainly used for producing large series of trusses in a factory. On site mostly separate plates and nails are used.